At Blade-Pro, we specialize in providing safe, efficient, and value-added services for your wind turbine blades. Whether you require inspection and maintenance services for your blades or service teams, our experienced team is here to assist you.

With over 25 years of experience in the industry, our team has worked with some of the most prominent wind companies, from design to manufacturing and service. We take pride in our extensive knowledge and expertise in blades.

At Blade Pro Consultancy, our goal is to always deliver high-quality, safe, and reliable services. We strive to provide you with the most precise possible picture of what needs to be done for long-term success.

Expertise in cutting-edge blade technology

Blade Pro offers a vast pool of industry knowledge and experience, ensuring you get top-notch advice and solutions tailored to your needs

Cost-effective solutions

Their proven methodologies help streamline operations, making your business more efficient and productive

Flexibility in our services

Our services are customized to meet the unique needs of various industries, enhancing operational efficiency.

Innovation

They stay ahead with cutting-edge approaches to service and maintenance, helping your business remain competitive

Result Driven

They focus on tangible improvements to your bottom line, ensuring you see real benefits from their services.

Worldwide Service Offerings

Quality & Damage Inspections

Comprehensive evaluations to assess the quality and identify any damages.

Technical Due Diligence

Thorough assessments ensuring compliance with technical standards.

Development of Blade Repair Processes and tools

Creating effective procedures for the repair of blades.

Maintenance Assessments

Evaluating maintenance practices to enhance operational efficiency.

RCA Investigations

Conducting Root Cause Analysis to identify underlying issues.

Audits

Practical and Theoretical Training Documentation and Support

Providing comprehensive training materials and support for effective learning.

Schedule a meeting to discuss your wind turbine blade service needs and goals.

Conduct a thorough assessment of your service need for damage or maintenance.

Execute the tailored service plan with minimal disruption to operations.

Blade Pro Consultancy offers a tailored approach to wind turbine blade maintenance, ensuring optimal performance for your specific needs. By combining cutting-edge technology with our team's extensive expertise, we deliver comprehensive inspections that adapt to various turbine models, blade designs, and environmental conditions.

Tailored inspection services for quality damage assessments

We offer inspection solutions that can be adjusted according to specific requirements.

Our services are designed to cater to the distinct demands of different sectors.

Our approach accommodates both small and large clients, ensuring everyone gets quality service.

We conduct thorough evaluations to assess quality and identify any damages present.

Quality Damage Assessments and Inspections

We conduct thorough visual inspections to identify visible damages and defects.

Utilizing NDT methods allows us to evaluate materials without causing any harm.

Our advanced imaging technologies provide detailed insights into internal structures and potential issues.

We ensure all findings are documented comprehensively for future reference and accountability.

Our services are customized to meet the unique requirements of various industries, ensuring relevance and effectiveness.

Blade Pro Consultancy provides a comprehensive and customized approach to evaluating wind turbine assets, ensuring optimal solutions for your unique operational challenges. Our team of seasoned experts meticulously assesses every aspect of your wind farm, from blade integrity and structural components to electrical systems and performance metrics.

We customize our TDD process to meet the unique requirements of each client, ensuring relevance and effectiveness.

These typically include reviewing design, manufacturing processes, and quality control.

Evaluate the blade design to ensure

it meets industry standards

and project-specific requirements.

This review examines the manufacturing

processes to identify potential issues

affecting blade performance or longevity.

Assesses the quality control measures

during manufacturing

to ensure consistency and reliability.

These involve more detailed assessments, including site visits, performance evaluations, and risk analysis.

On-site inspections to evaluate the blades condition and identify any visible defects or damage.

Analysis of blade performance data to identify deviations from expected performance metrics

Identifies potential risks associated with the blades, including material defects, design flaws, and operational issues.

For projects requiring highly specialised assessments, such as advanced material analysis or failure investigations, costs can be higher and are often quoted on a case-by-case basis

Advanced testing of blade materials to ensure they meet the required specifications and standards.

Detailed analysis of blade failures to determine the root cause and recommend corrective actions.

Evaluate the potential environmental impacts of the blades, including noise, shadow flicker, and wildlife interactions.

Enhancing Operational Efficiency through Comprehensive Analysis

A thorough examination of existing procedures to identify strengths and weaknesses.

Pinpointing specific processes that require improvements for better performance.

Applying optimized procedures derived from comprehensive audit results to ensure quality repairs.

Enhancing Efficiency through Regular Reviews and Innovations

Delivering tailored solutions for blade repair and maintenance needs

We conduct thorough evaluations to understand the specific requirements of your blades and operational context.

Crafting customized maintenance strategies tailored to enhance performance and lifespan of the blades.

Implementing ongoing assessments to adapt maintenance strategies as per operational changes and technology advancements.

Enhancing Blade Repair Efficiency Through Advanced Techniques

Blade Pro Consultancy offers invaluable insights that drive continuous improvement and operational excellence in wind energy projects. By meticulously investigating incidents, failures, and performance issues, our RCA experts uncover the underlying causes that may not be immediately apparent.

Understanding the Importance and Implementation of RCA It can help with preventing, improving your process, enhancing safety and quality, but also cost saving

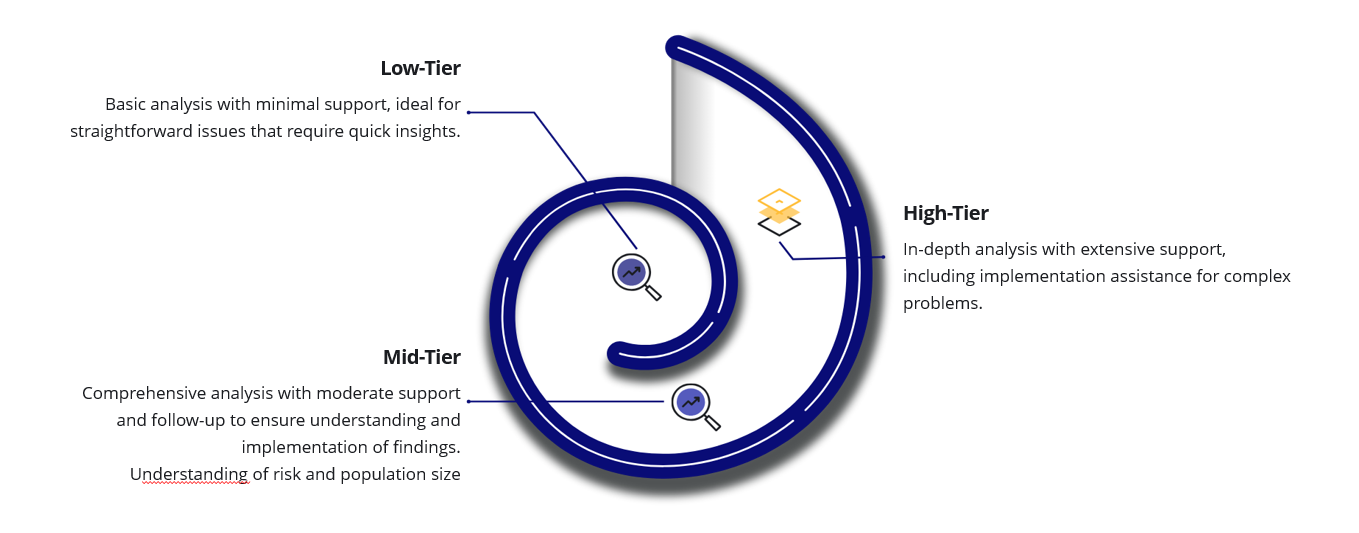

Exploring tiered Root Cause Analysis services for varied needs

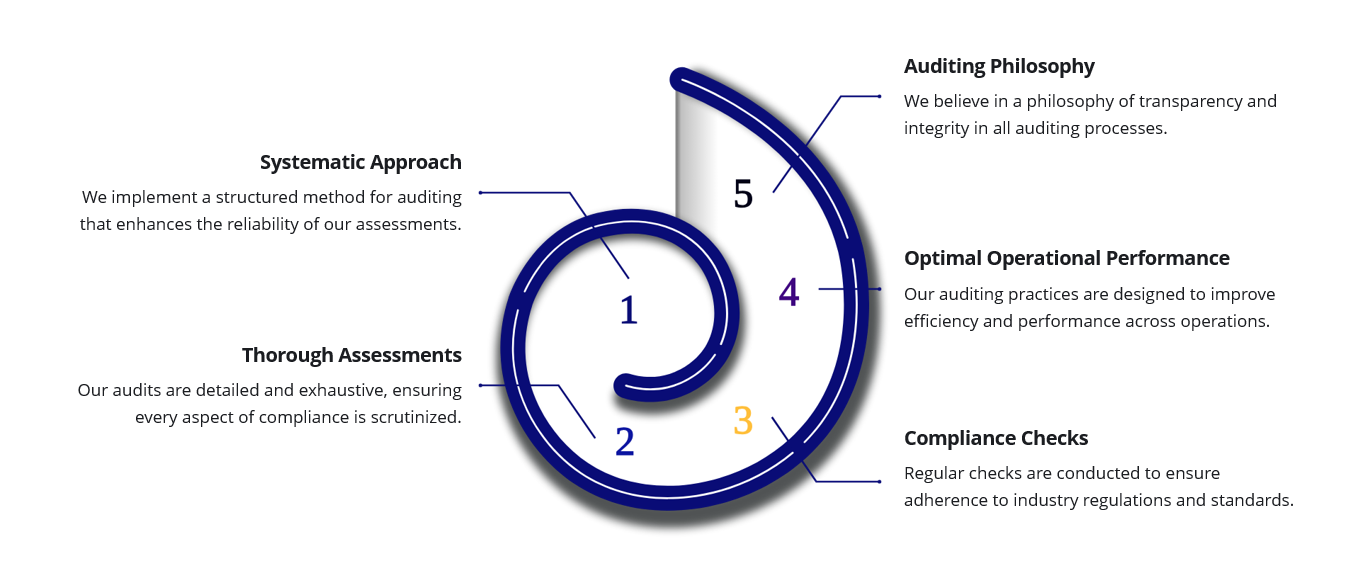

Understanding the Critical Role of Auditing in Business Processes

Promoting Blade Pro Consultancy: Auditing Processes

A Comprehensive Approach to Auditing Excellence

At Blade Pro Consultancy, we understand the significance of cost in today's wind industry, particularly when it comes to blade-related expenses. Our expertise lies in helping you efficiently and intelligently reduce these costs.

Structured Process for Cost-Saving in Wind Turbine Blade Manufacturing and Blade service companies

Enhancing Efficiency and Cost Management in Wind Turbine Services

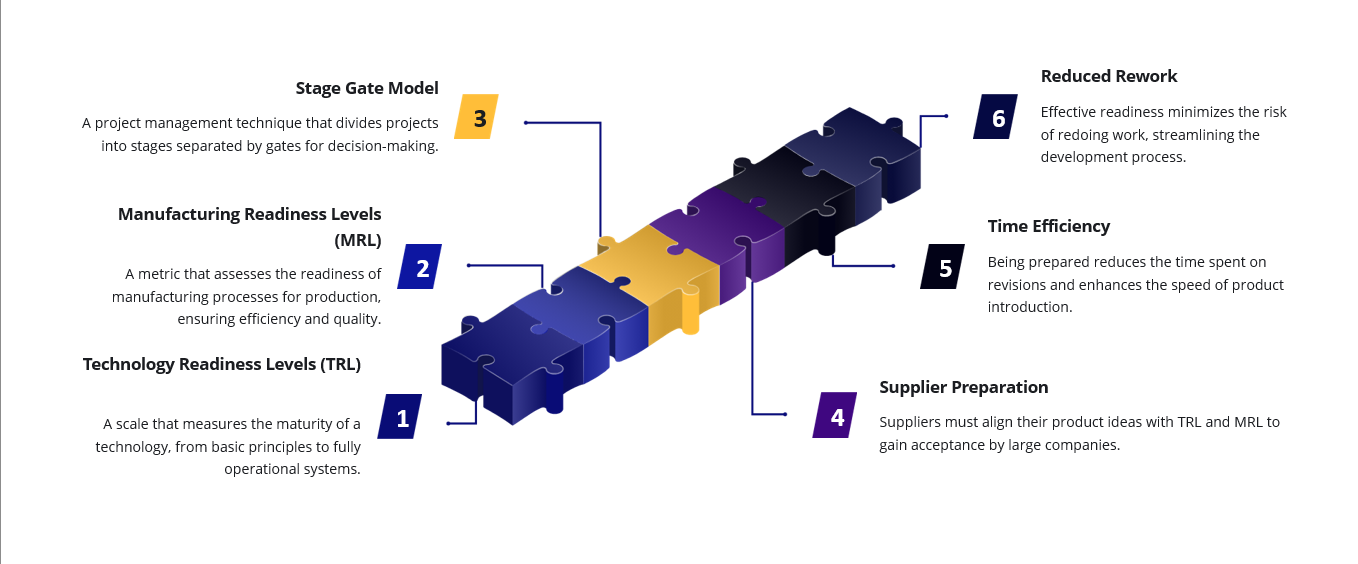

Exploring an effective stage gate model and its benefits for suppliers and technology readiness.

Advanced Stage Gate Model Support grooves through the development process, jamming at distinct stages separated by "gates."

Stages:

Gates: Decision points where the groove is evaluated, and the project can either move forward, be remixed, or be dropped.

Focus: Provides a structured framework for managing the development process, ensuring that each stage hits the right notes before moving to the next.

At Blade Pro, we take pride in our innovative approach to sales, perfectly aligned with industry-leading readiness standards. Our "TRL Triumph Sales" celebrates technology readiness with every transaction, ensuring that our products meet the highest benchmarks of innovation and reliability. Complementing this, our "MRL Mastery Sales" demonstrates our commitment to manufacturing excellence, mastering every aspect of production readiness to deliver superior products and unparalleled customer satisfaction.

By excelling in both Technology Readiness Level (TRL) and Manufacturing Readiness Level (MRL), we guarantee that every sale represents the pinnacle of technological advancement and manufacturing precision, setting new standards in the industry.

Understanding TRL and MRL enables suppliers to streamline their processes, reducing the time taken to bring products to market.

By clearly defining product readiness, suppliers can avoid costly mistakes and revisions, ensuring smoother transitions through production phases.

Suppliers who are well-versed in TRL and MRL demonstrate reliability, which can attract major companies looking for trustworthy partners.

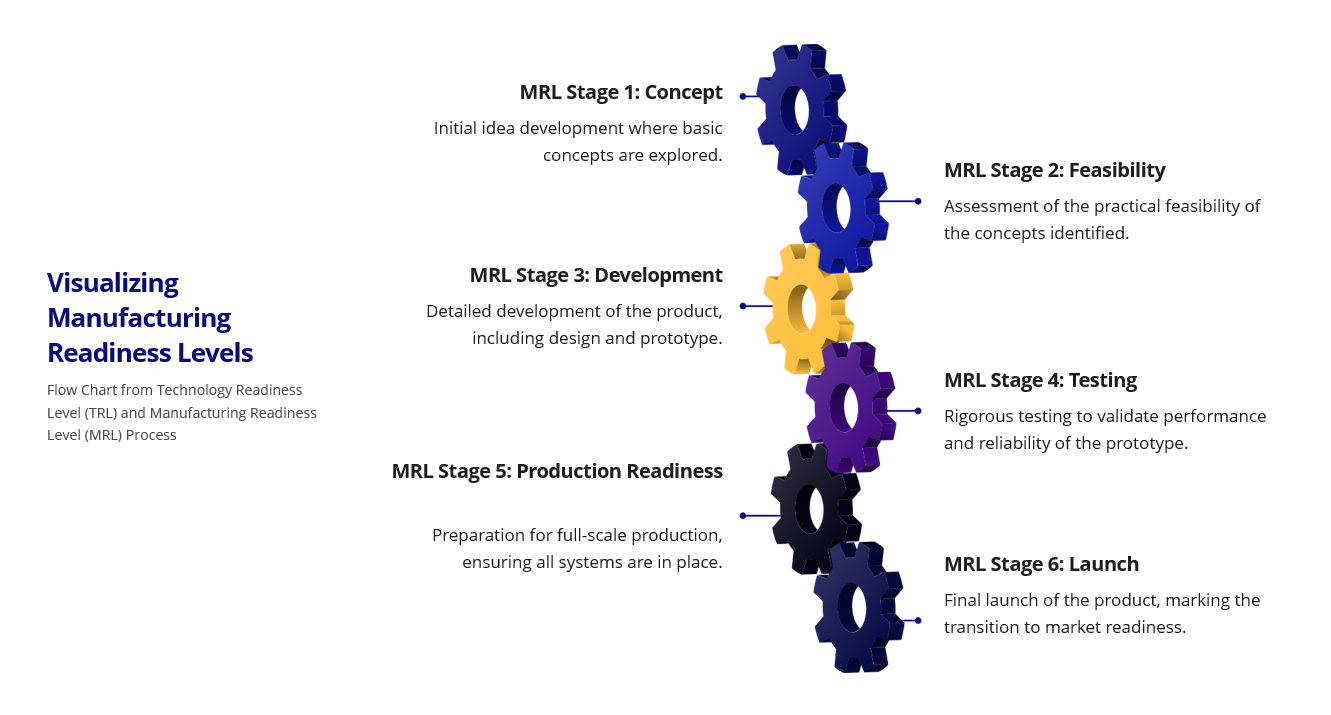

Flow Chart from Technology Readiness Level (TRL) and Manufacturing Readiness Level (MRL) Process

Discover Our Cutting-Edge Blade Solutions. Contact Us