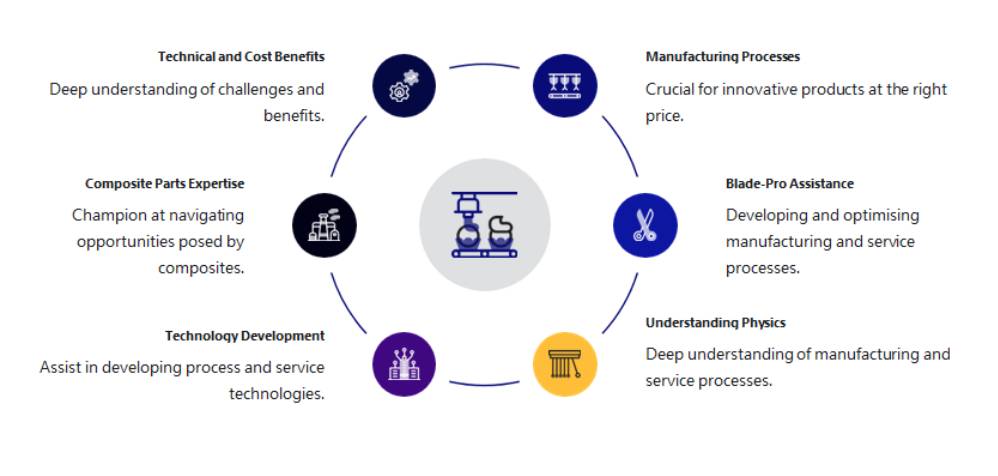

At Blade Pro, we are at the forefront of process development and optimization for the manufacturing of composite parts. With years of expertise and a deep understanding of the intricate physics behind manufacturing and service processes, we empower our customers to achieve unparalleled efficiency and quality in their composite production.

Our mission is to revolutionize the composite manufacturing industry by providing cutting-edge solutions that address the unique challenges and opportunities presented by composite materials. Whether you're in the wind energy sector, yacht industry, or any field utilizing composite materials, Blade Pro is your trusted partner in elevating your manufacturing processes to new heights.

As a global consultancy and service partner in the renewable energy market, Blade Pro leverages its 35 years of experience to deliver tailored solutions for operational efficiency. Our comprehensive methodology encompasses strategy deployment, goal setting, and the implementation of robust management systems, ensuring clients stay ahead in an ever-evolving industrial landscape.

Streamlined processes reduce time and resource wastage.

Consistent and well-defined processes lead to higher quality outcomes.

Efficient processes reduce operational costs.

Well-documented processes ensure compliance with regulations and standards.

Clear processes improve employee understanding and engagement.

Blade Pro offers a wide array of services designed to address every facet of composite manufacturing

Enhance efficiency and quality in manual layup processes, develop best practices for consistent results, and train personnel in advanced hand lamination techniques.

Design and optimize mould and resin delivery systems, develop precise process parameters for various part sizes and complexities, and troubleshoot and refine existing infusion processes.

Focus on mold design and optimization for efficient resin flow, process parameter development for various resin systems, and strategies for cycle time reduction and quality improvement.

Develop efficient trimming and machining processes, optimize surface preparation and painting procedures, and implement quality control measures for finished parts.

Design repair procedures for damaged composite structures, develop non-destructive inspection techniques, and create maintenance schedules to prolong component life.

Develop advanced techniques to maintain aerodynamic profiles and design tooling for efficient and consistent blade production.

Create innovative tools and processes, develop automated systems for increased productivity, and implement robotic systems for precise and repeatable processes.

Develop comprehensive quality assurance protocols, implement advanced non-destructive testing methods, and create data-driven quality control systems for continuous improvement.

Utilize advanced software to simulate and optimize manufacturing processes, predict and mitigate potential issues before production, and optimize material usage to reduce waste.

Provide comprehensive training programs for your workforce, develop custom curricula tailored to specific processes, and offer ongoing support and education to keep your team at the cutting edge.

At Blade Pro, we're committed to pushing the boundaries of what's possible in composite manufacturing. Our team of experts is ready to tackle your most challenging process development and optimization needs, ensuring that your composite production is always at the forefront of efficiency, quality, and innovation.

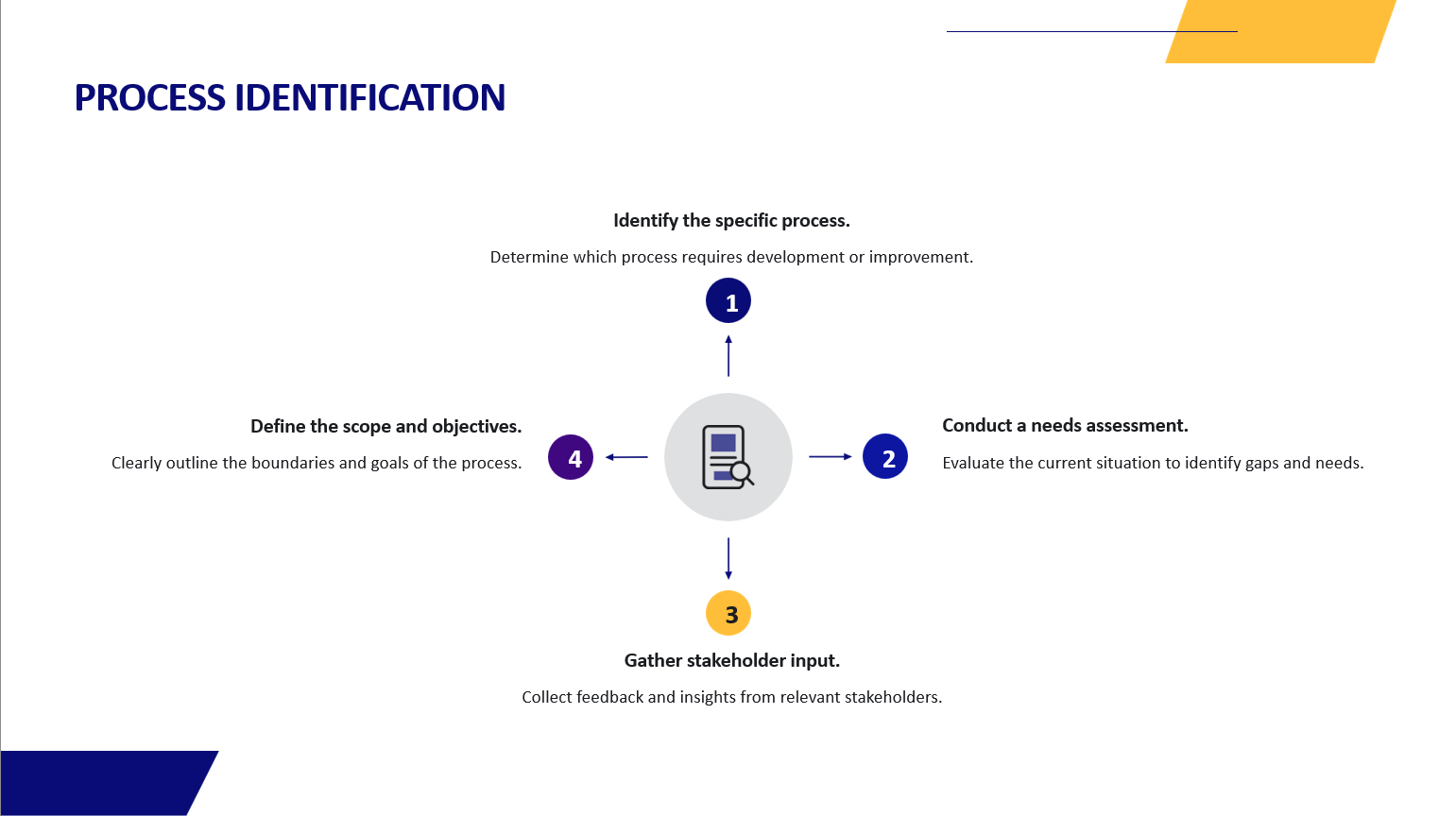

Process identification is essential in business analysis and improvement. It involves recognizing and documenting processes within an organization, including inputs, outputs, and key activities. This approach helps managers and analysts understand work flow, identify bottlenecks or inefficiencies, and find areas for optimization.

At Blade-Pro, we specialize in effectively mapping out processes to help organizations streamline operations, reduce waste, and improve productivity

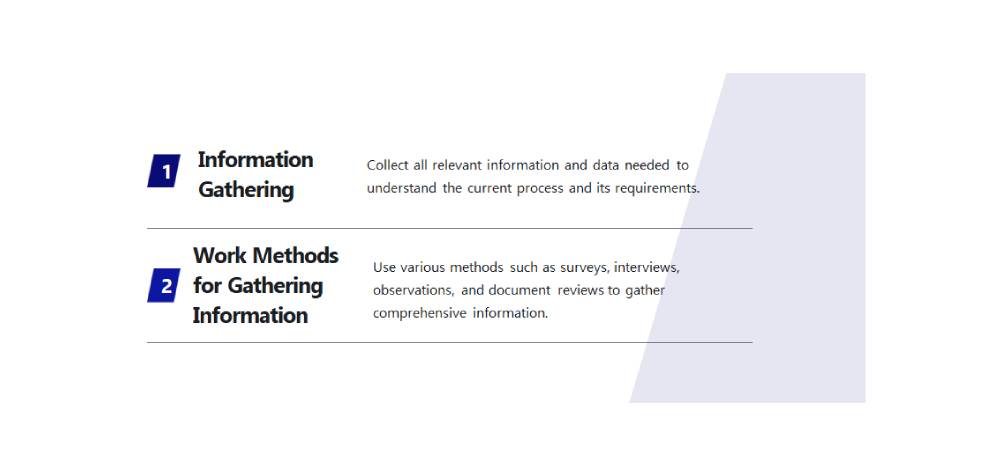

Blade-Pro employs advanced artificial intelligence techniques for efficient information gathering. The system utilizes natural language processing and machine learning algorithms to quickly analyze and extract relevant data from various sources.

Information Gathering: Collect all relevant information and data needed to understand the current process and its requirements.

Work Methods for Gathering Information: Use various methods such as surveys, interviews, observations, and document reviews to gather comprehensive information.

Blade-Pro enhances efficient design and analysis through its advanced computational tools and streamlined workflow. By automating many time-consuming tasks and offering real-time feedback, Blade-Pro significantly reduces design cycles and improves overall efficiency in the product development process.

Process Design and Improvement: Design the new process or improve the existing one based on the gathered information.

Work Methods Used: Create process maps, flowcharts, and models. Analyze the process for efficiency, effectiveness, and potential bottlenecks.

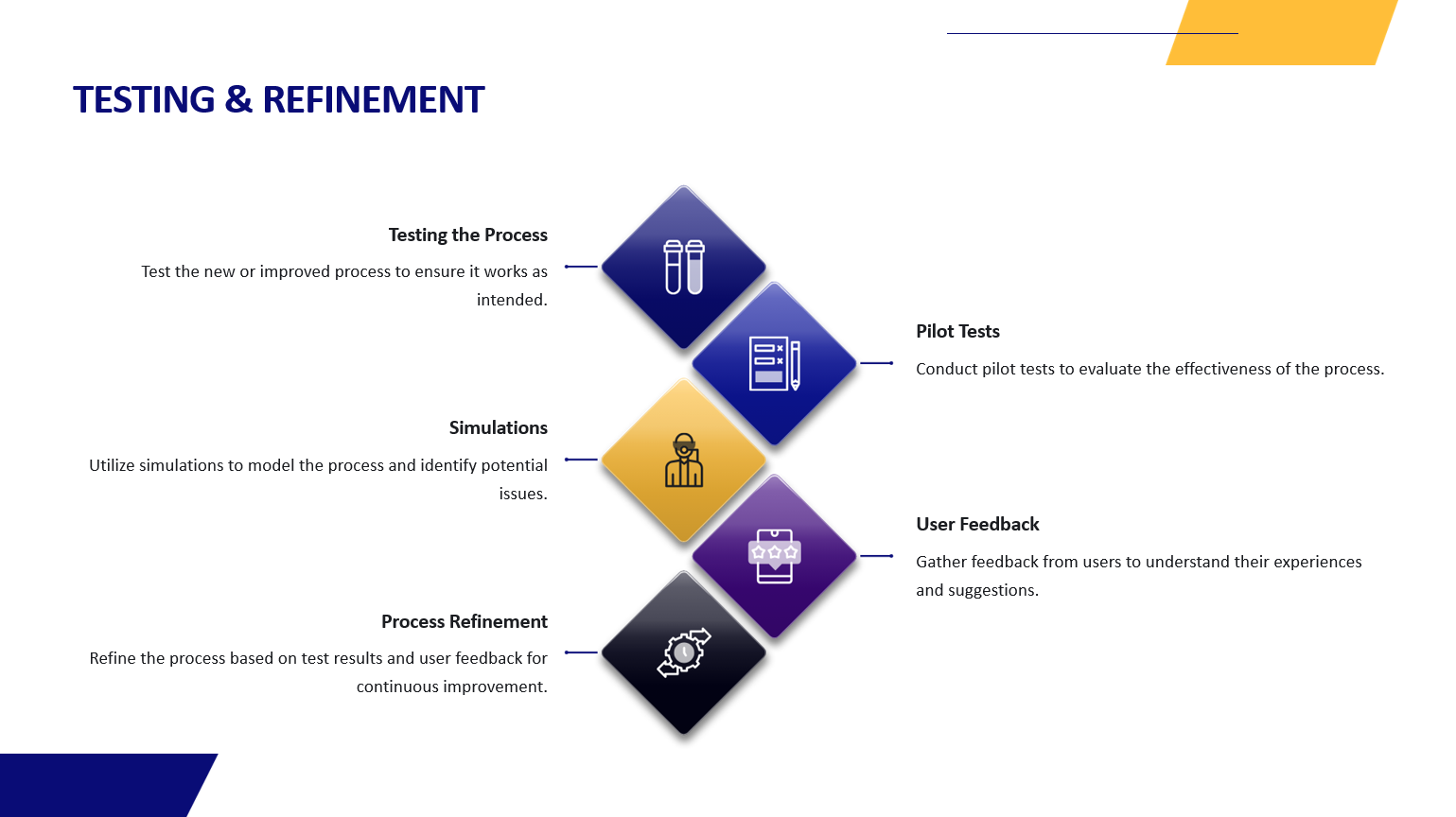

Blade-Pro employs a comprehensive approach to testing and refinement, ensuring optimal performance and reliability.

Blade-Pro excels in efficient implementation and monitoring through its comprehensive approach to process development and optimization. The company employs in-depth analysis of current processes, customized solutions based on composite physics knowledge, and seamless integration of cutting-edge technologies.

Blade Pro consultancy, we always watch the cost: We are Your Cost-Saving Sidekick!

At Blade Pro, we're not just about developing processes but about slashing costs and boosting

efficiency! During each step of our development process.

1. Cost-Saving Identification: We spot the savings you didn't know existed.

2. Implementation Strategy: We turn those savings into reality.

3. Monitoring & Evaluation: We monitor things to ensure you're always on track.

4. Client Collaboration: Your needs are our priority.

5. Sustainability Focus: Green and lean, that's our motto.

Join the Blade Pro revolution and watch your costs drop while your efficiency soars!